More than most technical procedures in the ancient world, drilling of hard stone such as quartz and granite has evoked awe and puzzlement. Neither wall paintings, nor textual information, nor excavated material has provided complete answers as to how drilling was done. As a consequence, there has been scholarly controversy. One such disagreement occurred between two eminent Egyptologists, A. Lucas and Sir Flinders Petrie. Their argument revolved around a difficult and important question, namely, how did the ancient Egyptians of the 3rd millennium B.C. drill granite?

This unresolved question, raised by Petrie as early as 1883, is important not only to Egyptologists, but to scholars of ancient lapidary technology anywhere in the world where hard stone was drilled. Here, we report on our preliminary experiments directed toward a resolution of this controversy. The reader must bear in mind that our work is based solely upon the evidence of the object examined, and does not take into account ancient Egyptian textual or material evidence that might shed light upon this problem.

The disagreement between Lucas and Petrie can be most accurately summarized by alternately juxtaposing their own words written over a 35-year period.

Lucas:

“…as neither copper nor bronze is sufficiently hard to cut such stones as basalt, diorite, granite, quartzite and schist, a harder material than the metal is required to do the work which must have been used either in the form of [fixed] cutting points [teeth] or as a loose [abrasive] powder . . . in my opinion, it was a loose abrasive powder [of] finely ground quartz sand used wet … loose quartz sand which occurs in great abundance in Egypt and will abrade quartz … which was the hardest stone the ancient Egyptians worked.”

Petrie:

“The cutting of granite was done by jewelled tubular drills . . . with cutting points . of emery . .. set in the sides of the tube both inside and out . .. every mechanic who has examined the grooves on .. . a core of red granite from Gizeh agrees that nothing but a fixed point could have cut such grooves.”

Lucas:

“In my opinion to suppose the knowledge of cutting these gem stones to form teeth and of setting them in the metal in such a manner that they would bear the strain of hard use and to do this at the early period assigned to them, would present greater difficulty than those explained by the assumption of their employment . . It is highly probable that pieces of the abrasive would have been forced into the metal, where they might have remained for some time . . and produced the same effect as intentional and permanent ones.”

Petrie:

… It seems physically impossible that any particle of a loose powder could become so embedded in a soft metal by the mere accidents of rubbing that it could bear the immense strain needed to plough out a groove of any considerable depth in such a hard material as quartz. … Modern diamond drill cores are clumsy and smudged work when compared to the Egyptian cores.”

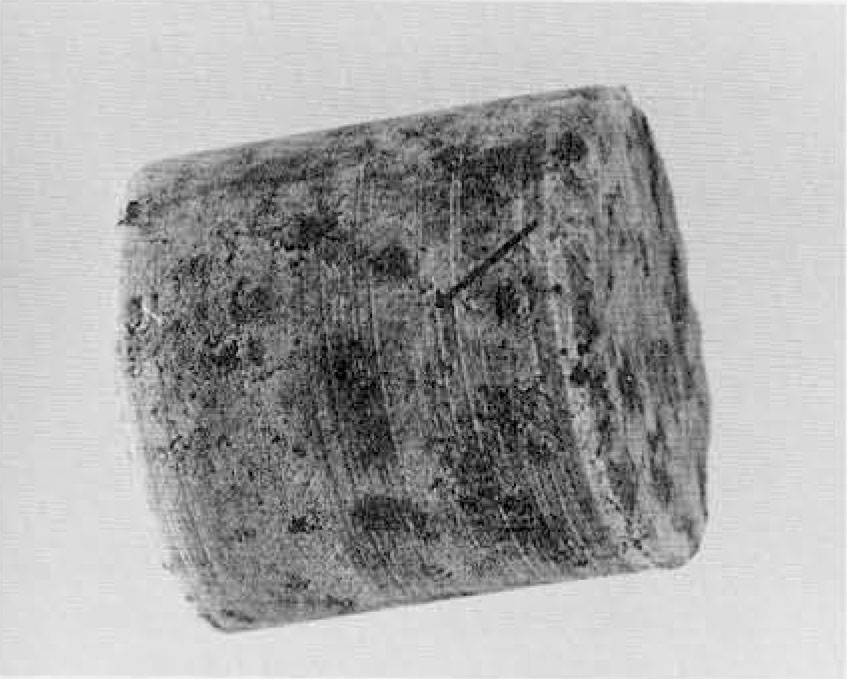

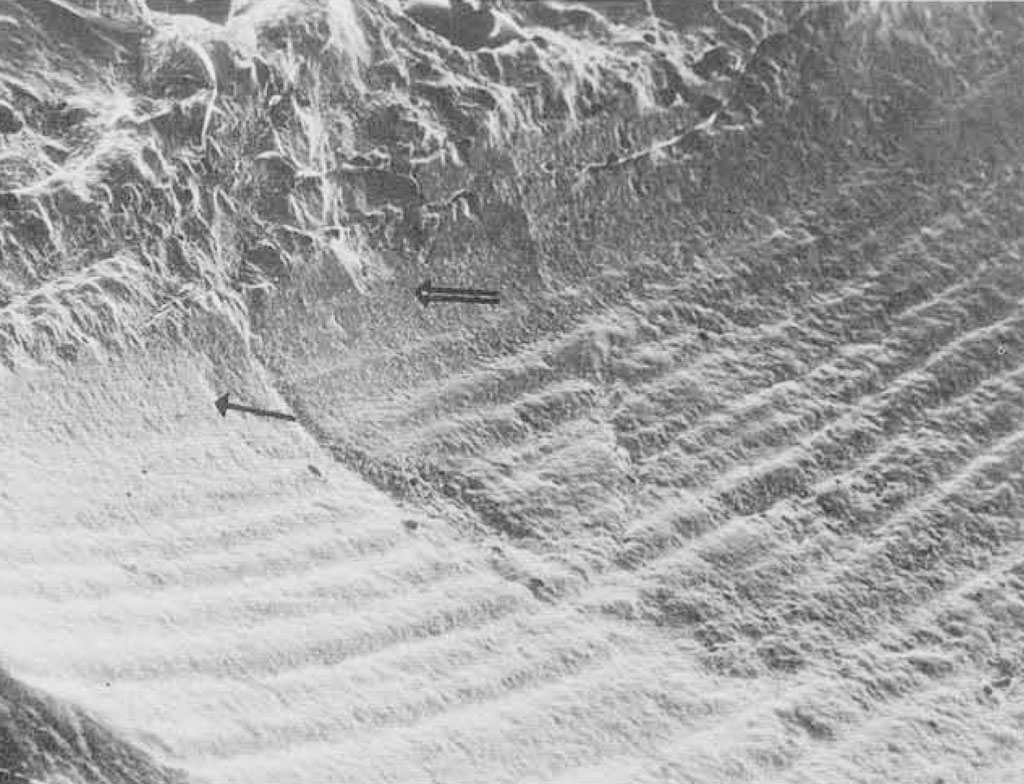

In essence, then, Lucas and Petrie, looking at the same regular concentric lines on drilled cores of granite (Fig. 1), disagreed as to whether they were made using a loose wet quartz sand abrasive (Lucas), or fixed points of emery (Petrie). (Note: Emery is a granular rock composed mainly of corundum—a crystalline compound of silicon and carbon—magnetite and spinel. Here, `emery’ and `corundum’ are used for the abrasive powders derived from these rocks.)

Lucas cited many references to show that quartz sand could drill granite. However, none of these references indicated that concentric lines were formed as a result of the drilling. Petrie speculated that diamond and corundum were used for drilling. He rejected diamond for its “rarity” and corundum for its “impossibility” in favor of emery. Neither cited evidence for his conclusions.

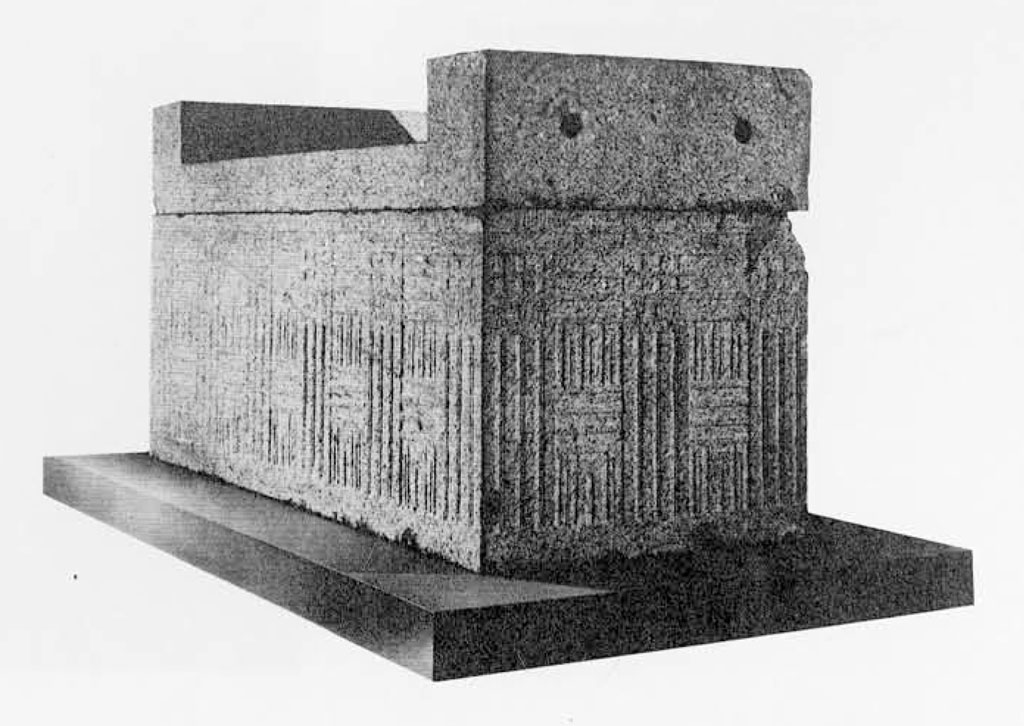

The purpose of our paper is to present experimental evidence which partly resolves this disagreement. Our evidence resulted from the functional analysis of a drilled granite lid from an Old Kingdom sarcophagus ca. 2500 B.C., now in the Brooklyn Museum (Fig. 2). It probably belonged to Prince Akhet-Hotep of Dynasty IV. The sarcophagus weighs about four tons, the lid two tons. The lid has two holes on each end that were (probably) used to raise and lower it. The holes are 24 cm. long; their diameter on the outside is 5.3 cm. and tapers to 4.3 cm. on the inside.

Method of Investigation

Some of the procedures that we have employed in this investigation have been previously reported. They have been used to analyze (1) beads from Shar-i-Sokhta, an Early Bronze Age site in eastern Iran; (2) ancient Near Eastern cylinder seals; (3) the drilled, inlaid teeth of the ancient Maya; (4) an Early Bronze Age Cycladic statuette, and (5) stone statuettes exhibited at the Cleveland Museum.

There are three separate steps in our method of investigation, all non-destructive to the object. They are (1) silicone impressions of the parts to be studied in order to capture the tool marks; (2) examination of the impressions (or epoxy models made from them) in the scanning electron microscope (SEM) and the fabrication of photomicrographs, and (3) functional analysis attempting to duplicate the tool marks experimentally.

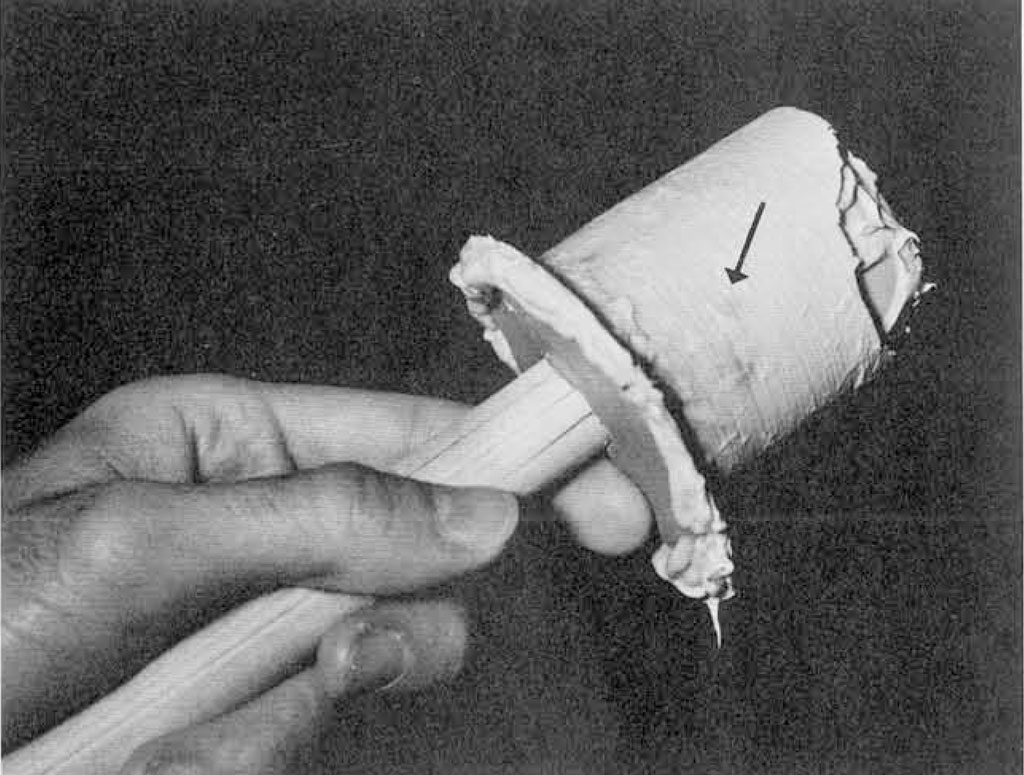

Ordinarily, when taking silicone impressions of a narrow drill hole on seals or beads, a toothpick has been used to tease the loose-flowing silicone into the hole. Because of the size of the drill holes in the lid, we had to resort to a modification.

In order to take an impression of the hole, a large dowel was used instead of a toothpick. Before the addition of the free-flowing silicone, a heavy-based silicone was placed around the end of the dowel and molded so that it was slightly narrower than the circumference of the hole. When this had set, free-flowing silicone was added and the dowel inserted into the hole. When the silicone had set, the dowel was removed first. This permitted the silicone impression to be removed more readily since it could be compressed slightly into the space occupied by the dowel. Because of the length of the drilling, the impression was made in two parts.

Findings on The Impression

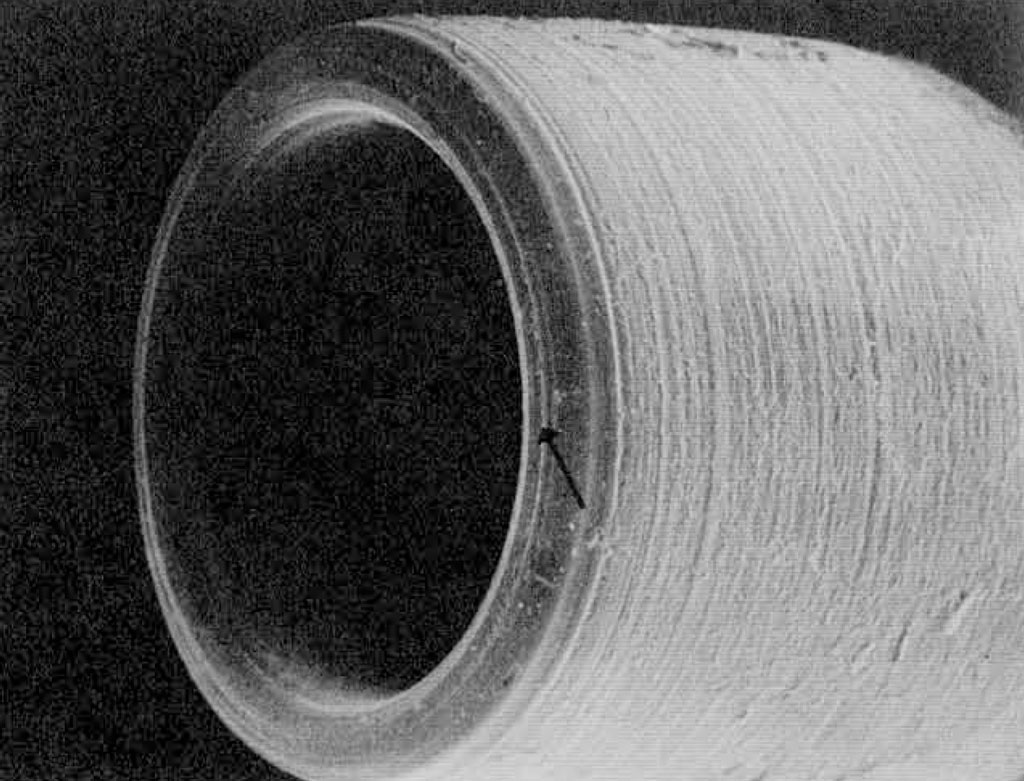

The regular concentric lines are clearly visible macroscopically on the impression (Fig. 3). They are quite similar to those found and reported by Petrie. Several characteristics are obvious from a study of the silicone impressions:

- The drilling was done entirely from one end with a relatively slight taper. Over the 24 cm. length of the drill hole there was only 1 cm. or 4% narrowing, indicating very little wear and wobble of the drill. This shape suggested the use of a tubular drill and will be discussed later.

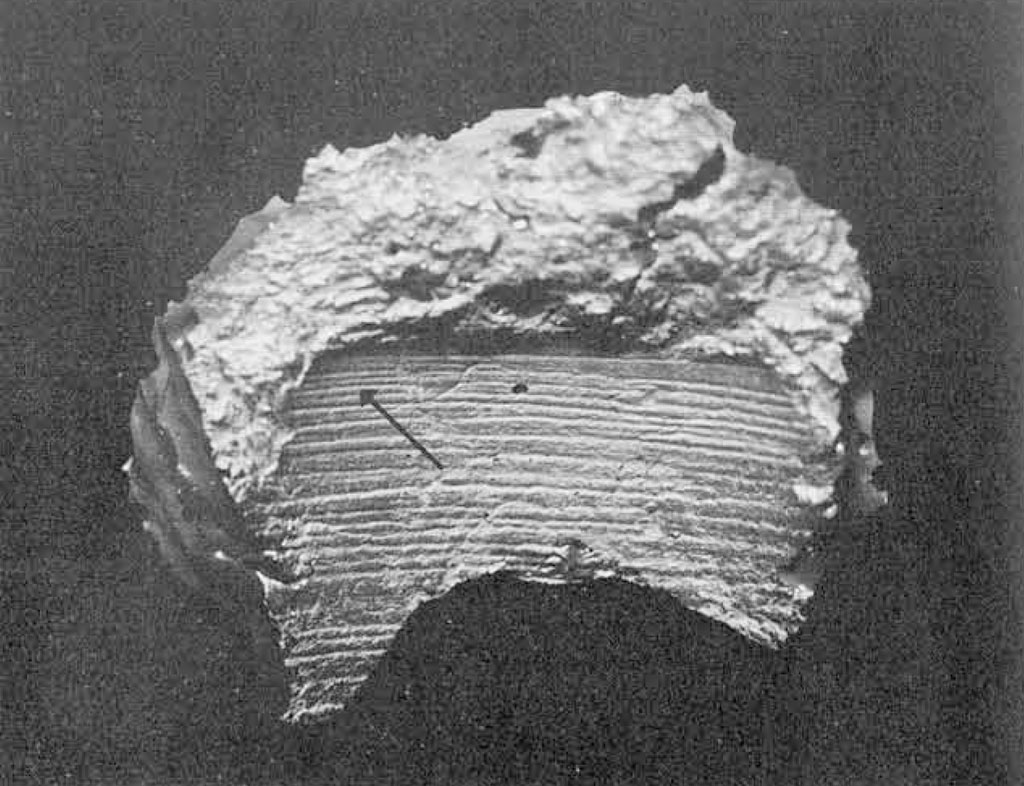

- The concentric lines were aligned more closely near the bottom or narrow end (Fig. 4).

- The concentric lines were not always perfectly parallel. Occasionally a line tracked at an angle across adjacent lines (Fig. 5). Some of the lines exhibited a slight amount of irregularity.

- At the edge of the narrow end of one of the holes, there is a region devoid of lines, slightly rounded and having almost a polished appearance (Fig. 6).

Functional Analysis

- A slab of red granite similar to that of the sarcophagus was drilled with a copper rod and/or a copper tube in conjunction with the following abrasives: (their Mohs scale of hardness is placed alongside in parenthesis) a, beach sand (7); b, crushed quartz (7); c, garnet (7); d, emery (9); e, corundum (9); f, silicon carbide (9); g, diamond (10).

Granite is composed primarily of quartz (7), feldspar (6) with some mica (2-3). - Drilling was also attempted with (a) chipped flint (7); (b) shaped sandstone (7); (c) shaped quartzite (7).

- The abrasives listed were used in the following manner (a) dry, (b) wet, (c) in a grease-like vehicle or lubricant, (d) in olive oil, (e) experimentally glued (by us) to a copper rod, (f) on a contemporary bonded drill.

- The size of the abrasives varied to include 60-90 grit and 240 grit.

- Drilling was effected at a constant rotational speed of 1000 RPM and held intermittently at a relatively constant pressure.

- Some drilling was done with a brace and bit in an oscillating (i.e. back and forth) manner and some with a bow drill.

- If the abrasive was not emery but maybe corundum or diamond, where would it have come from? They are thought not to be indigenous to Egypt. Could it have been by trade with the Far East?

- Were these minerals and/or the use of water or a lubricant known to the lapidaries of the surrounding regions? When and where did they start? Insight into this question may be gained by a functional analysis of other hard stones such as quartz and hematite that were used so widely in Mesopotamia. As we have shown in previous work, concentric lines are commonly found in the bores of cylinder seals.

- How does the use of an iron drill affect the formation of concentric lines and the speed of drilling?

- Can the presence or absence of concentric lines be used to determine between genuine and forged artifacts?

- The drilling was done first from one end, then the slab was sawn. This can be seen because a rounded lip remains on one side (Fig. 6).

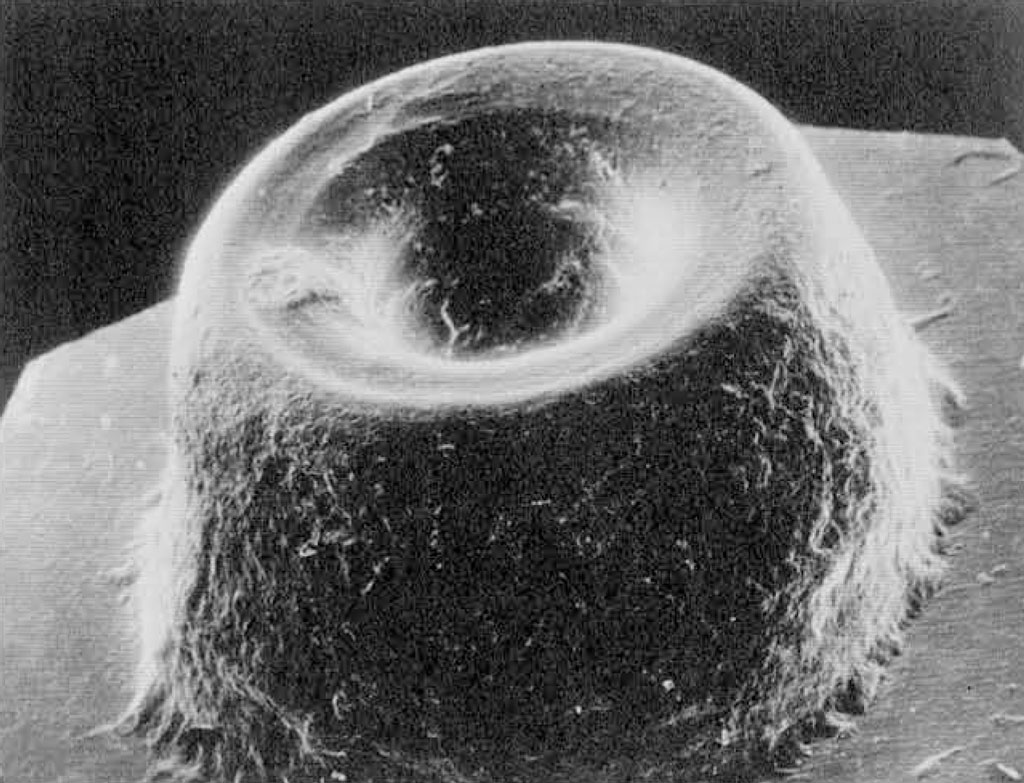

- The drill may have been a tubular drill. It was very likely copper, since bronze tools were not in use until the Middle Kingdom ca. 2000 B.C. The idea that it was tubular is based on our observation and measurements that a tubular copper drill creates a more parallel drill hole since it cannot wear beyond the internal diameter of the drill.

Another finding in our experimental drilling in favor of a tubular copper drill was the rounded, often polished end (Fig. 7). Where the drilling does not go completely through, this rounded, polished end is obvious. On the sarcophagus, there is the suggestion of these characteristics in one small section (Fig. 6). - The drilling was probably done while the lid was held in a vertical position. This would explain why the concentric lines are closer together towards the bottom (Fig. 4). Since the lid weighed two tons, it may not have been feasible to regularly and completely empty the worn abrasive and drilled granite debris from the bottom of the drill hole. Very likely, then, the abrasive would have been ground down and would have become finer and finer, producing closer and closer lines. The areas that appear polished may have been due to the finely pulverized granite debris which acted as a polishing agent.

- The abrasive used was either emery, corundum or diamond in conjunction with a vehicle such as olive oil.

Findings Using Silicone Impressions and Scanning Electron Microscopy

The clue that provided the basis for partly resolving the difference of opinion between Lucas and Petrie resulted from the experimental procedures described above. This happened when it became evident that it was possible to drill granite without creating concentric abrasion lines. Therefore, the presence or absence of concentric lines became an indicator of the type of abrasive. Consequently, an abrasive that could drill granite but did not produce cutting lines was ruled out as a possibility. This occurred when sand and crushed quartz were used with either a copper rod or copper tube. No lines occurred when these were added loose, either dry or wet (Fig. 7a). Thus, Lucas’ hypothesis that wet sand was the abrasive used is not supported, since the surface was totally rough (an examination of the drills after drilling with sand or quartz failed to reveal any charging of these to the copper). His second hypothesis, that attachment occurred during drilling, therefore, is also not supported by experiment.

On the other hand, Petrie may have been correct in one respect and possibly wrong in another: emery could have been used since we found its use with a copper tube produced concentric cutting lines (Fig. 7b), but it did not require that it be used as fixed points to create the cutting lines. While we were able to glue emery to a copper rod and while lines were produced in granite, it did not advance fast enough in our experiment to produce concentric lines on side walls. There are many reasons for this, such as loss of the cutting edge of the fixed particles, wear of the glue, etc. Our gluing was done using a combination of hide glue and water glass (sodium silicate), both of which were within the technology of the ancient Egyptians. It is possible that there are methods of creating fixed points that we have not tried as yet, such as embedding abrasives in a melt of copper to produce the equivalent of a contemporary sintered drill. Further research is needed.

Emery did not produce concentric lines when it was used dry. It produced lines when used in a water slurry which helped to keep the abrasive at the drill site and on track so to speak. This would suggest that the ancient Egyptians were aware of the value of water as an aid to drilling, something that contemporary lapidaries still employ.

Emery also produced lines when used in conjunction with a viscous lubricant and with olive oil. These too served to keep the abrasive particles at the site of drilling. It is not possible to say for certain which method was used. Using a viscous lubricant also had the advantage of being able to create a drill hole faster than when water was used with the abrasive. Further research is needed to distinguish between the use of different vehicles for the abrasives.

In addition to emery, concentric cutting lines were also present after drilling with corundum and diamond. These occurred when the abrasives were used loose with water, olive oil or a viscous lubricant. Only diamond produced concentric lines when used loose and dry. Further research is needed to distinguish between drilling created by emery, corundum and diamond, and also between drilling with water or with a lubricant as an adjunct.

Experimental drilling with chipped flint, fashioned sandstone and quartzite neither produced concentric lines nor a drill hole on granite, thereby precluding their use. It is tempting to believe that emery was the abrasive used because of the well known statement by Pliny that emery or Noxium was available from Noxos. This may have been the Egyptian source for the abrasive. Another known source of emery is Turkey although there is no proof that it was known in ancient times.

It is also tempting to speculate that diamond was the abrasive used due to its tremendous efficiency. One reason for this efficiency can be seen in the graph by Woodell (Fig. 8) which shows that while emery and corundum are 9 on the Mohs scale and diamond is 10, there is a significant increment between them. Petrie also speculated on the use of diamond as the abrasive and then rejected it because of its “rarity.”

At this stage in our research, we cannot say for sure which one of the abrasives that created concentric cutting lines in the granite, i.e. emery, corundum and diamond, was the one that was used or indeed if all were known or used.

These preliminary findings raise a number of interesting questions such as:

The answers to these questions will provide considerable insight into the history of ancient lapidary technology.

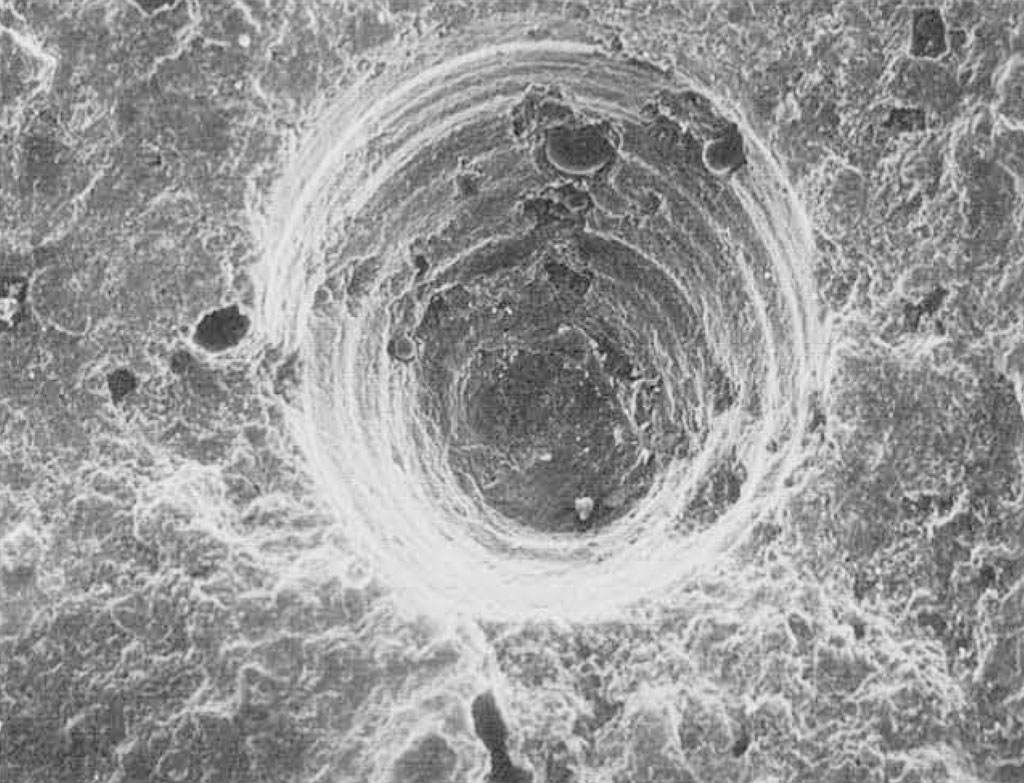

In regard to the drills made of sandstone or quartzite, neither produced concentric lines. Indeed, the extent of cutting was negligible. Flint was equally ineffective. In our previous research using flint on softer stone, such as marble, the pattern produced was that of concentric grooves (Fig. 9) that are related to the shape of the flint drill and created during the knapping process. These were readily distinguishable from concentric lines.

Regarding other aspects of the techniques used to drill the sarcophagus lid, while the evidence is less firm, the following suggestions are offered:

A. John Gwinnett is Professor of Oral Biology and Pathology at the SChool of Dental Medicine, Health Sciences Center, SUNY Stony Brook, New York.

Conclusion

A functional analysis of the drilling of a granite sarcophagus lid from the Old Kingdom period has begun to suggest resolutions to an important scholarly controversy between Petrie and Lucas, and has produced some preliminary insights into the hitherto speculative technology used. These are: 1) loose, dry abrasives (except diamond) did not produce concentric lines; 2) fixed abrasives or those in a watery slurry or a lubricant such as olive oil did produce concentric cutting lines; 3) corundum and diamond cannot be ruled out as not having been used to drill granite. These findings are significant in the history of ancient lapidary technology and will be useful in research on other stones. The discovery of the significance of the concentric lines, and also their significance as an indicator of the abrasive employed, will be useful for further research. Each type of stone will have to be dealt with separately.